PivaSystem

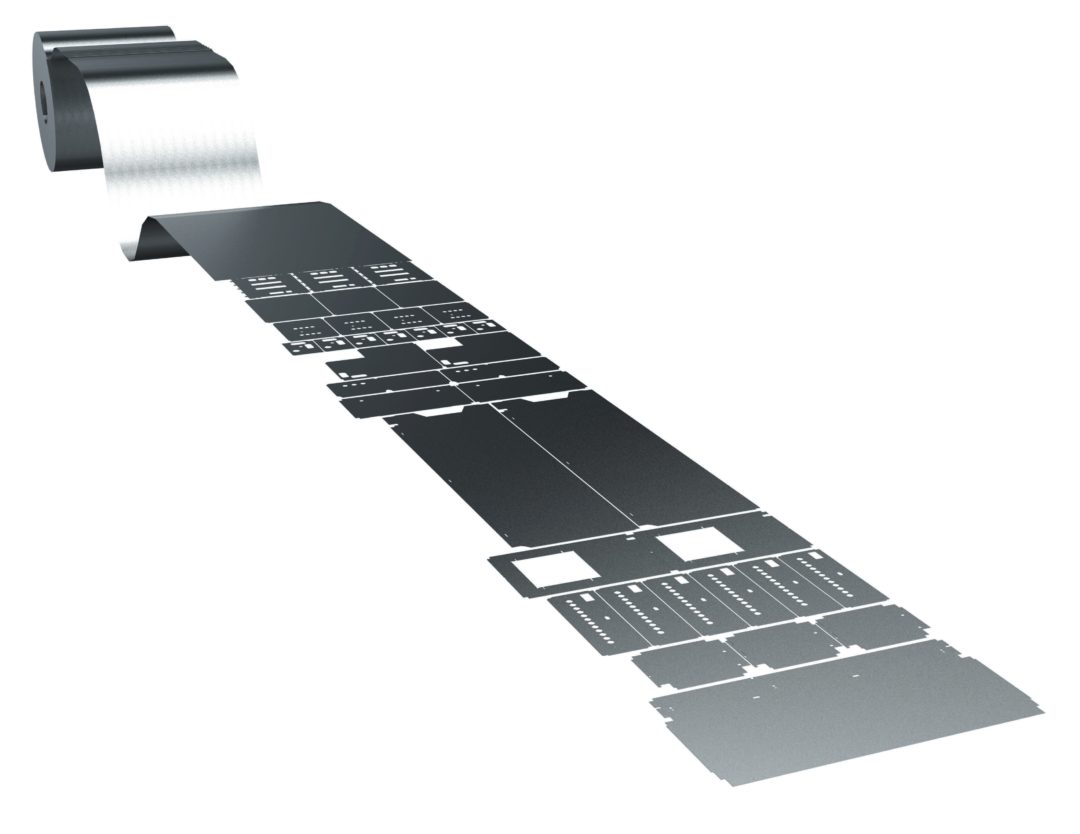

Pivatic’s PivaPunch and PivaBend are integrated production lines where blanked and formed parts are produced straight from the coil in one run.

Parts can run through wing benders but also be roll formed when applicable. Jobs such as welding and clinching are added when necessary to make your products complete in one run.

PivaPunch

PivaPunch is a programmable punching centre for coil material. It’s designed either for coils or for coils and blanks.

PivaPunch benefits:

- More efficient because it works straight from coil fully automatically, producing punched blanks stacked the way you need them.

- More flexible because it uses an advanced and freely programmable CNC coil punch system. Common coil width is used for a variety of parts produced in small batches, whereas true coil width is used for large series.

- End products are made complete ready in one process.

PivaBend

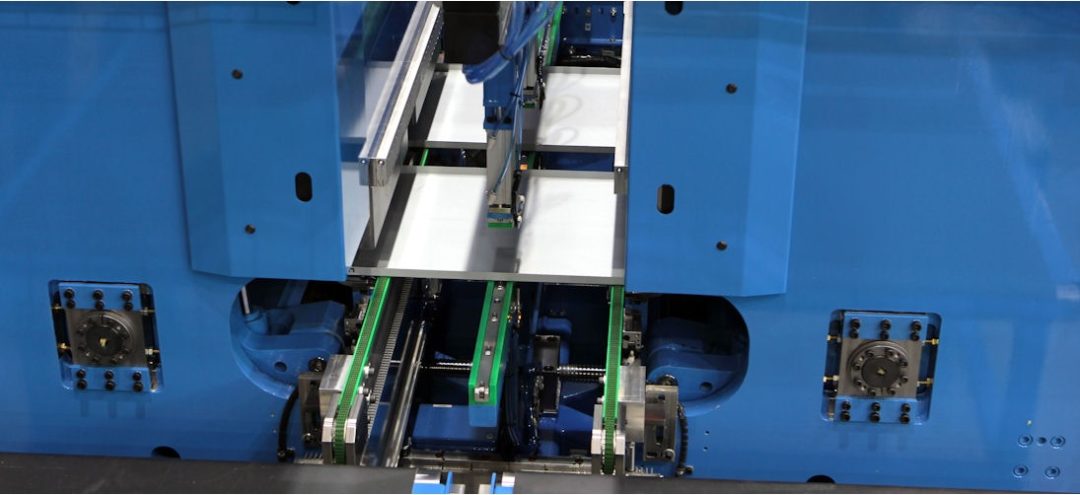

The PivaBend bending center is based on the wing bending method that makes it possible to form deeper enclosures in no-time.

It is used for sections, panels, or wrapper-type work pieces based on your production requirements.

PivaBend Benefits

- Panel and wing bending principle, suitable for sensitive materials such as pre-painted and stainless steel and aluminum.

- The cycle times for bending are often typically the same or nearly the same as for punching, keeping both PivaPunch and PivaBend fully loaded, typically 3 to 4 panels/minute, short panels 10 parts/minute.

- The tools, including the hold down tools in the station where the ends are bent, are engineered according to the geometry of parts to minimize or eliminate the need for tool changes.

Seesing Says

Producing straight from the coil creates remarkable efficiencies and ROI’s. Material utilization is almost 100% and material storage is considerably less than sheet material. Pivatic’s versatile coil punching and (wing) bending systems deliver reduced lead times, superior flexibility and fingerprint-free part output.

Let's Talk

How would you like me to contact you?